Tips and news

Explore our latest practical advice, discover our new products and find application examples.

The Paul Group has been recognized for many years for its expertise in the following areas: industrial sealing, insulation, acoustic and vibration elastomers and foams, hoses, sleeves, and Staubli fittings, as well as cutting and machining of technical parts (according to plans).

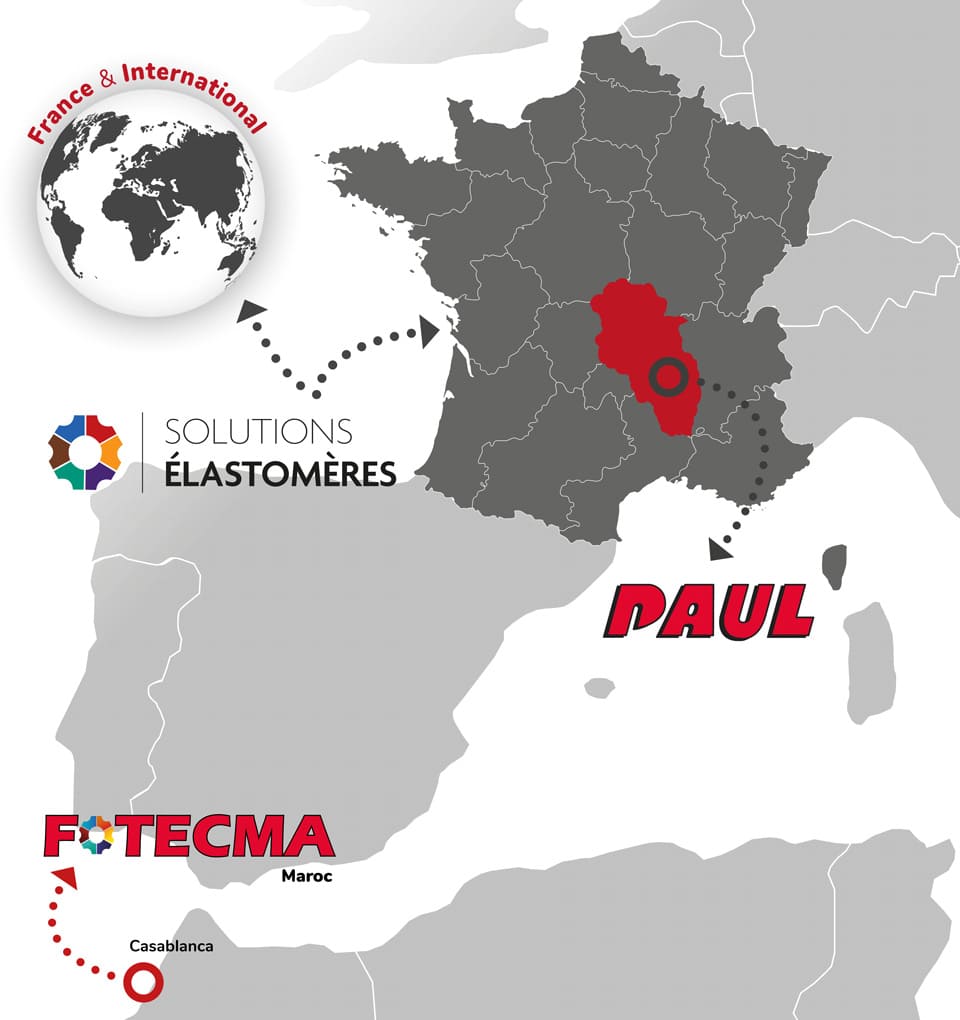

Located in the Loire department (42) in Saint-Étienne, the Paul Group consists of three complementary entities: Paul, Fotecma, and Elastomer Solutions.

Leading brands to serve you

Acoustic materials, anti-vibration, sealing, custom parts, and pipes for individuals and professionals.

The PAUL Group has been recognized for many years for its expertise in the following areas: Industrial Sealing, Acoustic and Vibration Insulation, Elastomers and Foams, Hoses, Sleeves and Staübli Fittings, as well as cutting and machining of technical parts (according to plans).

Located in the Loire department (Saint-Étienne - 42), the PAUL Group consists of three complementary entities :

- PAUL SAS: a historic family-owned company founded in 1946 (local activity – 4000 m² of stock - 2000 account customers)

- SOLUTIONS ELASTOMERES SAS: a company specialized in online sales since 2006 (France, Europe, Asia)

- FOTECMA*: a Moroccan partner company (Casablanca) specializing in building acoustic insulation since 2012 (*Moroccan Technical Supplies)

With 70 years of experience, the PAUL Group offers a wide range of technical products dedicated to industry. Our technicians are ready to advise you in the fields of Acoustic Insulation (machine tools, engines, pumps, generators, air conditioning, heating systems, ventilation systems, compressors, music rooms, recording studios, public spaces, buildings, wall soundproofing, home acoustic insulation, etc.), Anti-vibration (rubber suspensions, metal suspensions, elastic joints, anti-vibration pads, Gripsol pads, resilient materials, etc.), Sealing (O-rings, oil seals, cut seals, sealing braids), and Technical Parts (water jet cutting, extrusion, molding, turning, milling, hot lining, etc.).

Our four families of materials include: Rubbers (nitrile, natural, neoprene, EPDM, parablond), Polyurethanes (hardness from 30 to 99 Shore A), Technical Foams (rubber foams, polyurethane foams, silicone foams, acoustic foams, etc.), and High-Performance Elastomers (silicone, butyl, hypalon, Viton, etc.).

The PAUL Group maintains a significant stock of parts at its Saint-Étienne facility. Standard parts are delivered within 24 to 48 hours, while parts requiring special manufacturing (machining, molding, fabrication) are shipped within 1 to 3 weeks.

Over 90% of the price requests received are processed within 24 to 48 hours.