-

Acoustics

- Alveolar foam

- Composite foam

- Smooth side foam

- Rubber foam

- Melamine foam

- Fire classification foam

- Wall kit (renovation)

- Suspended acoustic panels

- Custom acoustic panels

- Panneaux acoustiques PET

- Soundproof underlayment

- Pipe Insulation ST GK

- Heavy bitumen sheets

- Technical glues

- Acoustic accessories

- Soundproof wall insulation

- Soundproof floor insulation

- Soundproofing for machines

- Studio acoustic foam

- Soundproofing for rooms, restaurants...

- Acoustic panels

-

Antivibratory range

-

Trouver votre solution d’isolation antivibratoire

- Armoires électriques

- Broyeurs

- Cabines d'engin

- Capotages

- Climatisations - CTA

- Compresseurs

- Containers et emballages

- Cribles et trémies

- Dalles et planchers flottants

- Equipements informatiques

- Groupes électrogènes

- Machines-outils

- Matériels de contrôle

- Matériels embarqués

- Matériels de laboratoires

- Moteurs, moteurs de bateau

- Mur

- Plafonds

- Pompes

- Ponts roulants

- Presses et cisailles

- Transformateurs

- Tuyauteries

- Tables Vibrantes

- Ventilateurs

- Custom Anti-Vibration Mounts

- Rubber suspensions

- Super Resilient rubber

- Ressorts anti vibration

- Gripsol plates

- Flexible bushes

- Bitumen heavy masses

- Metal suspensions

- Regufoam® Vibration

- Supports Marin

- SYLOMER PAD

- Flexible couplings

- Anti-vibration hanger

- HUTCHINSON Paulstra

- AMC Mecanocaucho

-

Trouver votre solution d’isolation antivibratoire

- Tightness

-

Materials shop

- Made-to-measure

- Hoses

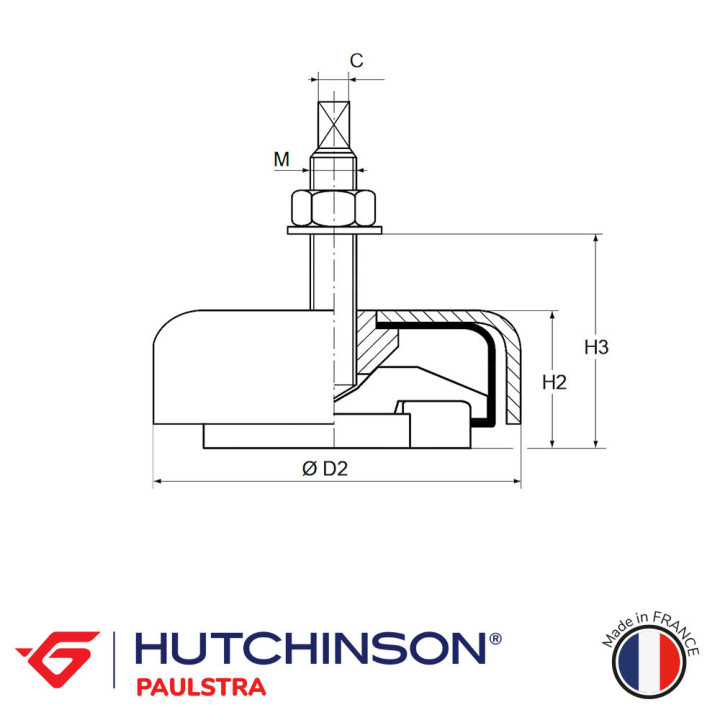

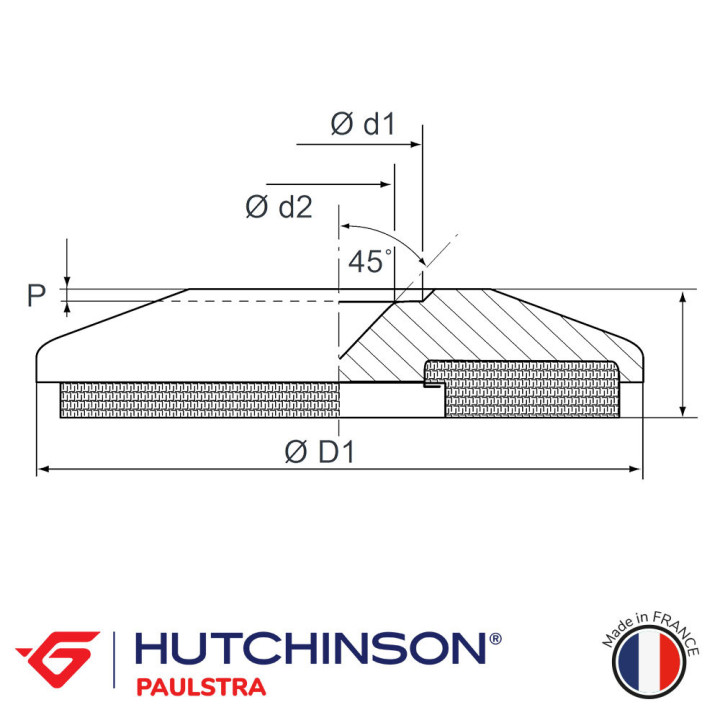

SE121 MOUNTINGS

Référence :

V43

Standard SE121 mountings have a cast steel base and a resilient element made from a stainless steel wire cushion.

En savoir plus

-

ReferenceV43

Téléchargements

Accessoires