-

Acoustics

- Acoustic panels

- Alveolar foam

- Composite foam

- Smooth side foam

- Rubber foam

- Melamine foam

- Fire classification foam

- Wall kit (renovation)

- Suspended acoustic panels

- Custom acoustic panels

- Panneaux acoustiques PET

- Soundproof underlayment

- Pipe Insulation ST GK

- Heavy bitumen sheets

- Technical glues

- Acoustic accessories

- Soundproof wall insulation

- Soundproof floor insulation

- Soundproofing for machines

- Studio acoustic foam

- Soundproofing for rooms, restaurants...

-

Antivibratory range

-

Trouver votre solution d’isolation antivibratoire

- Armoires électriques

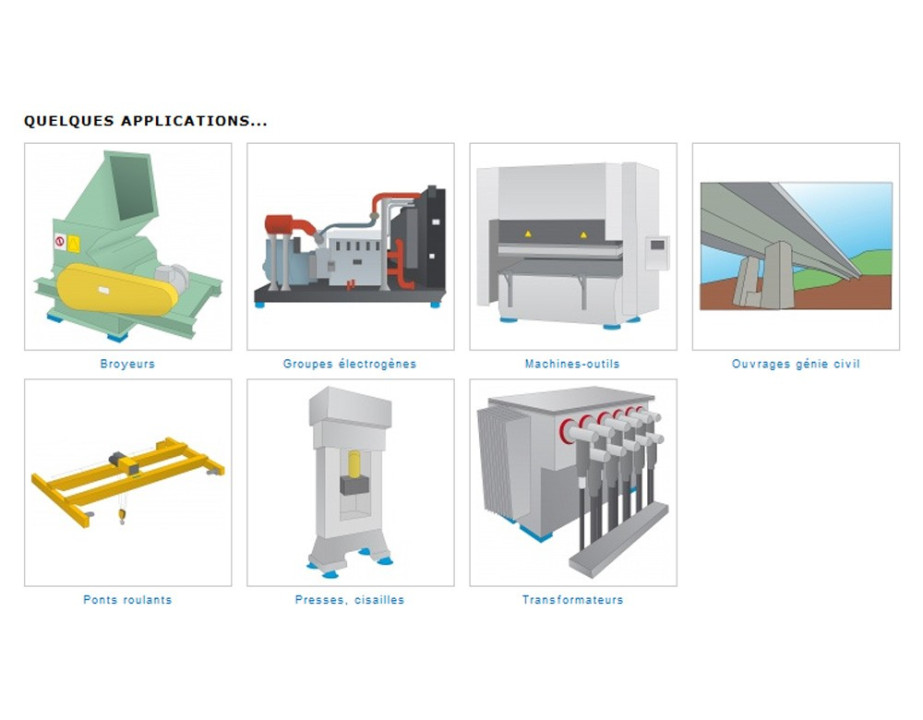

- Broyeurs

- Cabines d'engin

- Capotages

- Climatisations - CTA

- Compresseurs

- Containers et emballages

- Cribles et trémies

- Dalles et planchers flottants

- Equipements informatiques

- Groupes électrogènes

- Machines-outils

- Matériels de contrôle

- Matériels embarqués

- Matériels de laboratoires

- Moteurs, moteurs de bateau

- Mur

- Plafonds

- Pompes

- Ponts roulants

- Presses et cisailles

- Transformateurs

- Tuyauteries

- Tables Vibrantes

- Ventilateurs

- Custom Anti-Vibration Mounts

- Rubber suspensions

- Super Resilient rubber

- Ressorts anti vibration

- Gripsol plates

- Flexible bushes

- Bitumen heavy masses

- Metal suspensions

- Regufoam® Vibration

- Supports Marin

- SYLOMER PAD

- Flexible couplings

- Anti-vibration hanger

- HUTCHINSON Paulstra

- AMC Mecanocaucho

-

Trouver votre solution d’isolation antivibratoire

- Tightness

-

Materials shop

- Made-to-measure

- Hoses

SE114 MOUNTINGS

Référence :

53960745

he SE114 mounting comprises one or more layers of elastomer bonded to flat, parallel metallic plates.

These mountings may be cylindrical or rectangular. They are designed to withstand very high compressive loads. The range of mechanical characteristics is governed by the hardness of the rubber and the number of intermediate metallic plates.

En savoir plus

-

Reference53960745

Téléchargements